The PP IV Pharmaceutical Project in Iraq

The PP IV pharmaceutical project in IRAQ aims to establish a state-of-the-art facility dedicated to manufacturing and distributing essential medications. This initiative is designed to meet the healthcare needs by ensuring reliable access to high-quality pharmaceutical products.

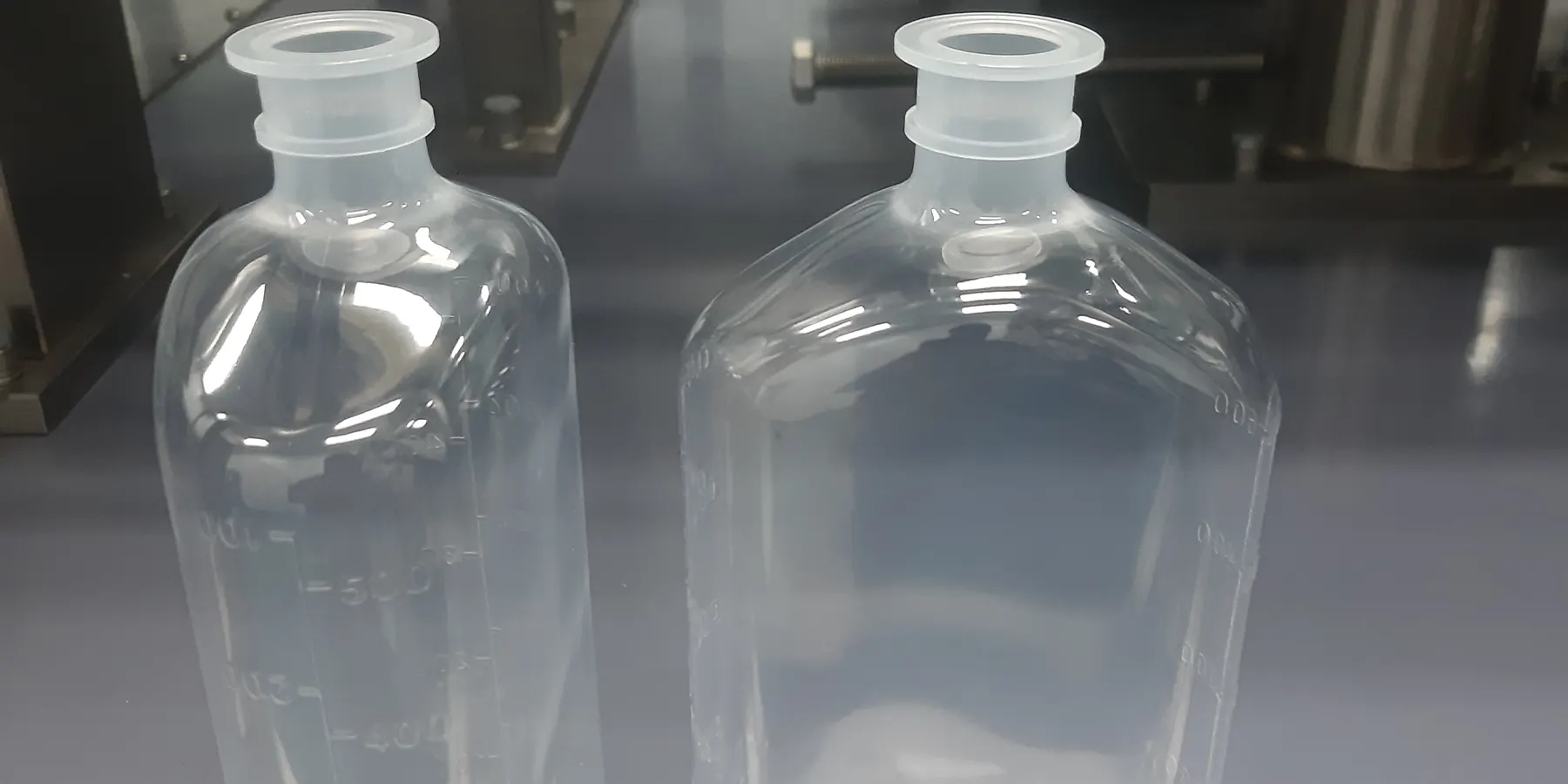

ISBM Line: Cost Effective as compared with Glass Bottle

CE CERTIFIED

Automatic Line

Preforms with Built-in Hangers

Key Points:

- High-Speed Filling = 4500 BPH @500ml

- Filling Accuracy = ±1.5%

- Range = 100ml – 1000ml

Plus:

- User Friendly Equipment

- Dedicated After-Sale Support

- Cost Effective

Task

We ensured the timely manufacturing and shipment of machines with accessories, successfully conducting the FAT with the customer. For the SAT, we executed a series of tasks: inspecting the machine for placement suitability, verifying mold installation in the injection machine, and performing a dry run of the mold without material. Following QC approval, we initiated production, transferred the cooled blown bottles to the SBM machine, and sent them for QC checks. After QC approval, we set up the Filling Machine, performed CIP and SIP, conducted trial runs for proper filling and capping, and prepared validation documents. Post QC approval, we commenced production runs, continuously verifying that the bottle shapes met specifications.